An efficient and sustainable alternative for the public lighting of the future

PAMPLONA —19/2/2025— In the outdoor lighting industry, material selection plays a key role in product durability, efficiency, and sustainability. Historically, aluminum and steel have been the predominant materials in luminaire manufacturing. However, technological advancements have paved the way for more innovative and environmentally responsible solutions. Among them, engineering polymeric materials have proven to be a superior alternative in numerous technical and environmental aspects.

Resistance and durability without corrosion

One of the main challenges in outdoor lighting is exposure to harsh weather conditions, ranging from high humidity to marine environments with salinity. Metallic materials such as steel and aluminum require additional treatments to prevent corrosion, whereas polymeric materials are completely immune to this issue.

Thanks to their composition, technical polymers maintain their structural integrity over time without the need for coatings or constant maintenance, which represents a significant advantage in operational costs and sustainability.

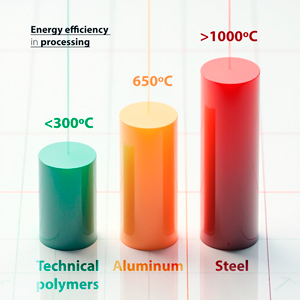

Energy efficiency in processing

Manufacturing luminaires with metallic materials involves high-energy consumption processes. Aluminum, for example, has a melting point of 650 °C, while steels exceed 1,000 °C, resulting in a significant energy demand during processing. In contrast, technical polymers can be molded at temperatures below 300 °C, significantly reducing resource consumption and, therefore, the environmental impact of production.

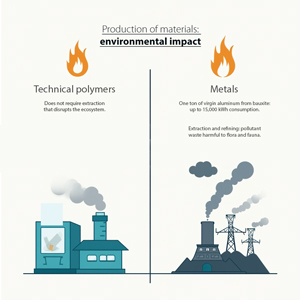

Reducing the ecological footprint in raw material extraction

Extracting metallic materials such as aluminum has a strong environmental impact. Producing one ton of virgin aluminum from bauxite can require up to 15,000 kWh of energy and generate solid and gaseous waste that severely affects ecosystems. In contrast, polymers can be manufactured from raw materials through less aggressive processes, with a reduced ecological footprint.

Recyclability, energy recovery, and circular economy

Polymeric materials offer the possibility of being recycled and revalorized for energy recovery. Their calorific value is comparable to that of coal, enabling efficient energy recovery at the end of their life cycle. Additionally, most technical polymers can be reprocessed without losing their mechanical properties, contributing to a more efficient circular economy.

Eliminating paints and polluting coatings

Unlike metallic materials, polymers are naturally immune to corrosion, eliminating the need for protective paints and coatings. This presents a significant environmental advantage, as the production and application of industrial paints generate volatile organic compound (VOC) emissions, hazardous waste, and high energy consumption.

The coatings industry significantly contributes to air pollution and the deterioration of air quality. By using mass-tinted materials, these polluting processes are eliminated, reducing toxic waste generation and minimizing environmental impact.

ATP Lighting: specialist in high-quality polymeric lighting solutions

Since its inception, ATP Lighting has developed luminaires made from engineering polymeric materials, creating corrosion-proof, highly resistant, and sustainable products. Thanks to its focus on innovation, the company has developed patented technologies that optimize the performance and durability of outdoor lighting.

Today, ATP offers highly efficient solutions with minimal maintenance, backed by a comprehensive 10-year warranty, even in extreme conditions of humidity, temperature, and salinity. With over 50 years of experience, this brand continues to lead the way in the industry, providing advanced and sustainable solutions for more efficient and durable public lighting.

An efficient alternative for the future

Polymeric materials represent an advanced solution in the manufacturing of outdoor lighting luminaires. Their resistance, lower environmental impact, and processing efficiency position them as a sustainable and cost-effective alternative to traditional materials. In a context where the industry must move towards more environmentally responsible solutions, the use of technical polymers stands out as a key strategy for a more efficient and eco-friendly future.

Press contact:

Julio Aparicio

ATP Lighting

comunicacion@atpiluminacion.com

Copyright © 2016 ATP Lighting Inc. All rights reserved. ATP Lighting, the ATP Lighting logo and all trade names listed on this website with the ® symbol are registered trademarks of ATP Lighting.

![[...]](https://www.atpiluminacion.com/xtra/imgs/loading.gif)